Froth Flotation Process Is Used for Concentration of Which Ore

Froth flotation is a process used to separate minerals suspended in liquids by attaching them to gas bubbles to provide selective levitation of the solid particles. Is based on the difference in wettability of different mineralsB.

Concentration Of Ores Hydraulic Washing Froth Flotation With Examples

Niccherip5 and 1 more users found this answer helpful.

. Sulphide ore is grounded and is dropped in a mixture of water and pine oil oil and water create a suspension. In Zimbabwe antimonite is mined together with lead and arsenic which are regarded as contaminants and hence the need to selectively remove them. Uses sodium ethyl xanthate C_2H_5OCS_2Na as collestor C.

In Zimbabwe antimonite is mined together with lead and arsenic Abstract Mineral ore beneficiation and value addition has become a key factor for economic growth in Africa. It is most extensively used process for the separation of chemically similar minerals and to concentrate ores for economical smelting. Collectors and stabilizers are used in the process of froth floatation.

A Fe b Al c Cr d Cu. Froth flotation magnetic separation Leaching are some of the commonly used processes of concentration. This is used in mineral processing paper recycling and waste-water treatment industries.

Uses pine oil as frothing agent. 2It is used for the extraction of those metals in which the ore particles are preferentially. For which ore of the metal froth floatation method is used for concentration.

A concentration of 2530 is suitable for economical smelting of copper. Selected Sep 16 2018 by faiz. It is used all through the minerals and particulate processing industries with notable examples in the processing of iron oxide ores coal phosphate ore potassium chloride.

Froth floatation process for the concentration of ore is an illustration of the practical application of Adsorption. It has the advantage over gravity separation because it can collect even the extremely fine particles of minerals. Froth flotation is used to raise the low mineral concentrations in ores to concentrations that can be more economically processed.

It has been described as the single most important operation. Froth flotation process is used to concentrate relatively low grade ores. Froth floatation method It is a process that selectively separates materials based upon whether they are water-repelling hydrophobic or have an affinity for water hydrophilic.

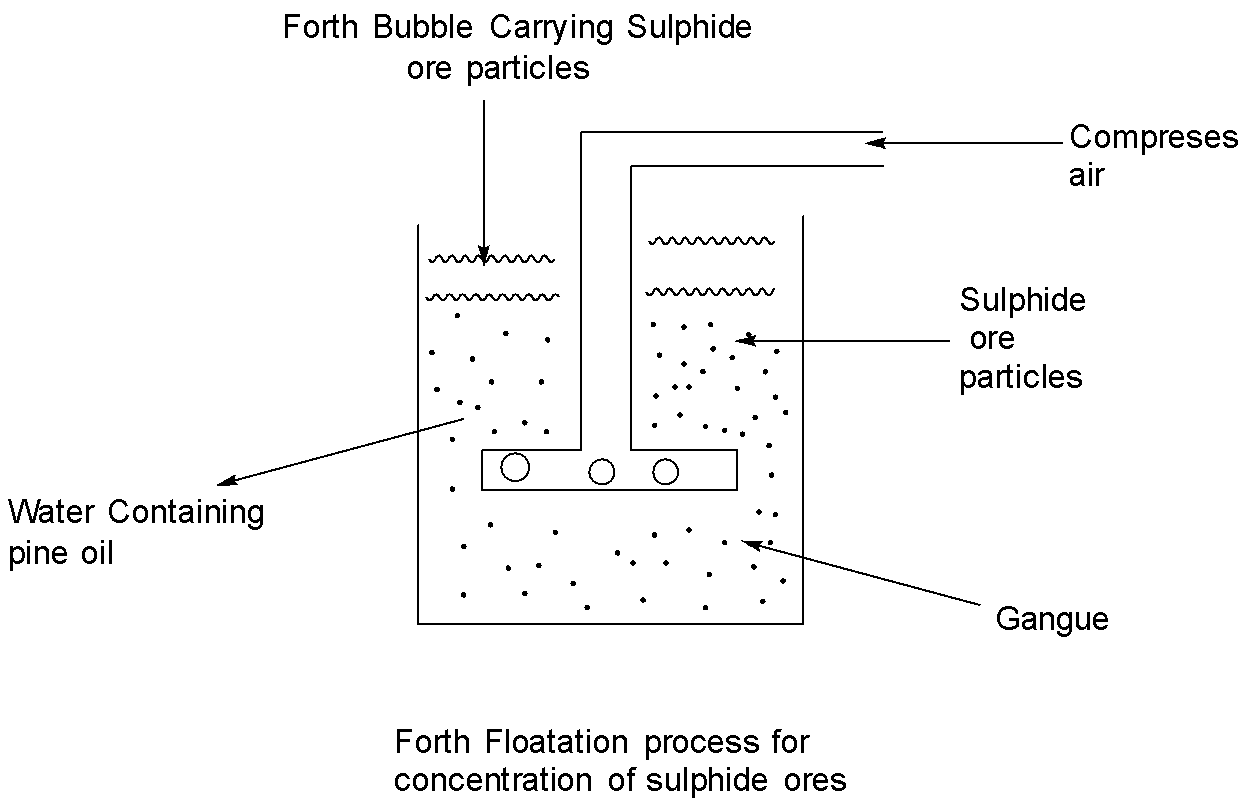

Uses pine oil as frothing. Click hereto get an answer to your question U SLUCILALUI 39. Froth floatation method is used for the concentration of sulphide ores.

Froth flotation works particularly well for sulfide minerals but it is not limited to them by any means. Froth flotation process is used to concentrate relatively low grade ores. A Horn silver B Bauxite C Cinnabar D Haematite.

After carrying out a froth flotation separation the products are as shown in Table 1. This is the process for concentration of primarily sulphide ores. Froth floatation process is used for the concentration of the ore of.

1321 Ore Beneficiation by Froth Flotation. We report on the selective concentration of antimonite at the expense of lead and arsenic by use of a depressant. The first process in the extraction of zinc is the concentration of the ore which is done by the Froth Floatation method.

Using this data calculate. Froth flotation is a process for selectively separating hydrophobic materials from hydrophobic. Used NaCN as depressant in the mixture of ZnS and PbS when ZnS forms soluble complex and PbS forms froth D.

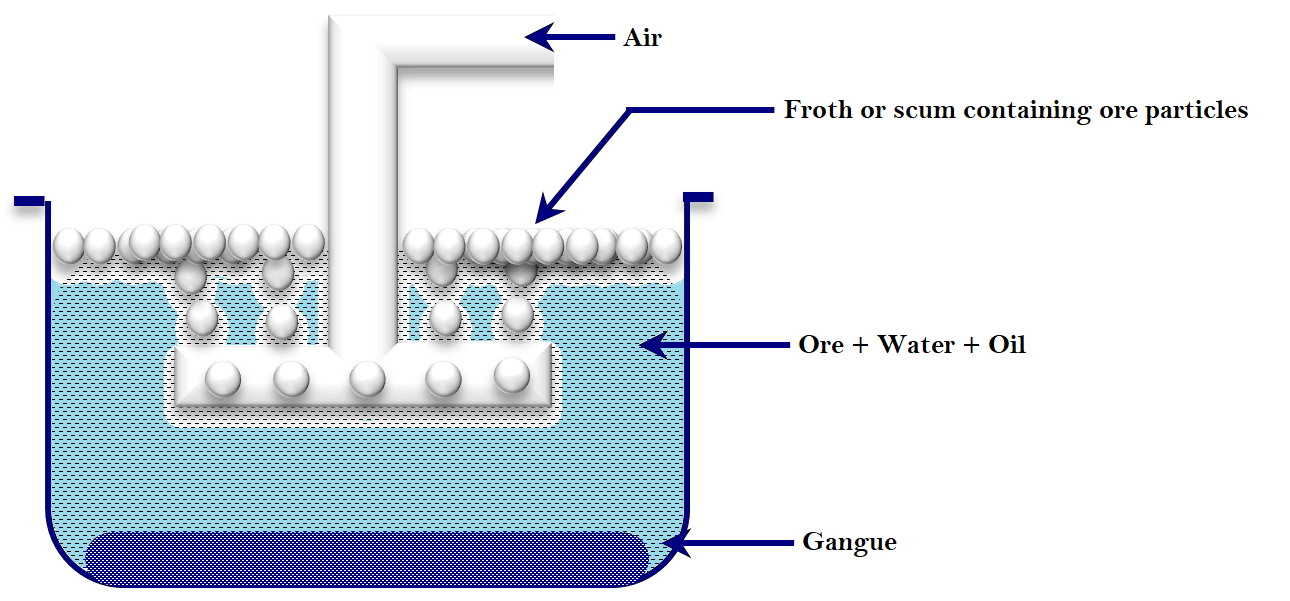

The process uses the difference in the wetting characteristics of minerals and gangue. Froth flotation process used for the concentration of sulphide oreThis question has multiple correct optionsA. This technique is based upon the wetting properties of the metal and gangue particles.

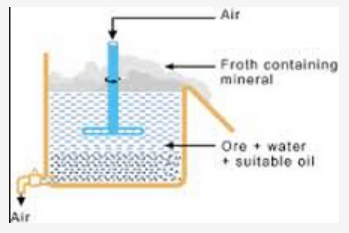

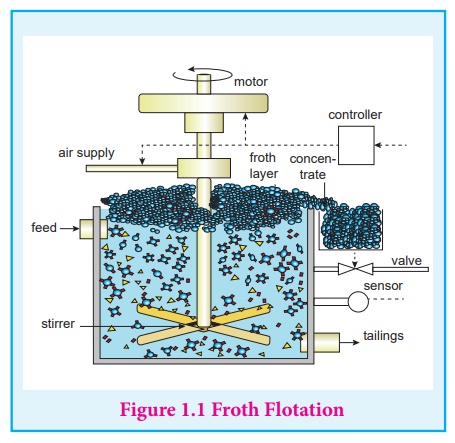

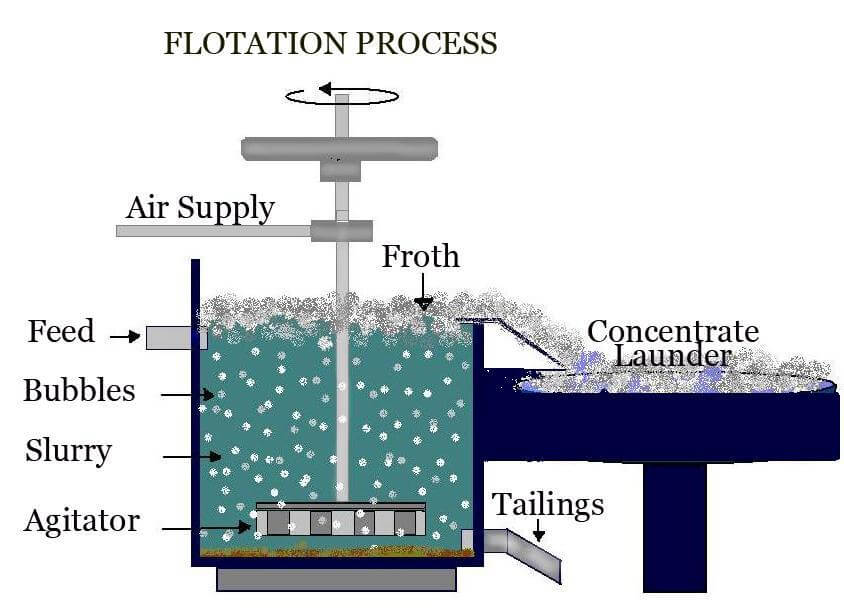

1 Froth floatation process is based on the principle of difference in the wetting properties. In this process the sulphide ore gets preferentially adsorbed over the impurities. In this tank the compressed air is blown through the agitator which is rotated.

We know that the froth flotation process is used to concentrate the sulphide ores. Of the ore and gangue particles with water and oil. Uses sodium ethyl xanthate C 2 H 5 OC S 2 Na as a collectorC.

Froth flotation process used for the concentration of sulphide ore. It is based on the principle that the gangue and ore particles have different wettability degrees with water and pine oil. Thus role of adsorption in froth floatation process can be understood as following processes.

Froth Flotation Process. In froth floatation process sulphide ore is shaken with pine oil and water the ore particles are adsorbed on froth that floats and the gangue particles settle down in tank. Froth flotation is a process for selectively separating of hydrophobic materials from hydrophilic.

Answer 1 of 8. This process is commonly used for sulphide ores and is based upon different wetting characteristics of ore and gangue particles. In some cases for example sulphides ores of copper.

Graderecovery performance of a hypothetical copper ore flotation process. Is based on the difference in wettability of different minerals. The finely powdered ore is mixed with water pine oil frother and ethyl xanthate or potassium ethyl.

A Ratio of concentration b Metal Recovery c Metal Loss d Weight Recovery or Yield e Enrichment Ratio Table 1. Uses NaCN as depressant in the mixture of ZnS and PbS when ZnS forms soluble complex and PbS forms frothD. Historically this was first used in the mining industry where it was one of the great enabling technologies of the 20th century.

Flotation is a selective process and can. Froth floatation process is based on the principle of difference in the wetting properties of ore and gangue with water and oil.

Froth Flotation Cell With Sensor Actuators And Control System The Download Scientific Diagram

Explain Froth Flotation Process Clearly Cbse Class 12 Learn Cbse Forum

Froth Flotation Process Youtube

Froth Floatation Process Used For The Concentration Of Sulphide Ore Which Of The Following Youtube

Describe The Methods Used To Obtain Concentrated Ores From Chemistry General Principles And Processes Of Isolation Of Elements Class 12 Cbse

Froth Flotation Process Detailed Explanation With Diagrams And Videos

Concentration Of Ores Metallurgy Chemistry

Explain The Purification Of Sulphide Ore By Froth Floatation Method

The Welfare Theory Is Based On

Froth Flotation Process Detailed Explanation With Diagrams And Videos

Sulphide Ore Is Concentrated By The Method 1 Froth Flotation Process2 Magnetic Separation3 Gravity Method4 Calcination Method

For Which Of The Following Ores Froth Floatation Method Class 12 Chemistry Cbse

Flotation Froth An Overview Sciencedirect Topics

Froth Flotation Method Ssc Standard 10 Brainly In

Draw The Diagram Showing Froth Floatation Method And Label Its Parts

Draw The Diagram Showing Froth Floatation Method And Class 12 Chemistry Cbse

Write A Short Notes On Froth Floatation Process Sarthaks Econnect Largest Online Education Community

Comments

Post a Comment